The choice between a metal and plastic visor is a critical decision when considering face protection, as each material offers distinct characteristics suited to different applications. Visors are an integral component of personal protective equipment (PPE), providing a barrier against impact, debris, and other potential hazards. Metal visors, commonly constructed from materials like aluminum or stainless steel, are renowned for their durability and strength. These visors excel in heavy-duty environments where robust impact resistance is essential, such as in industrial or construction settings.

On the other hand, plastic visors, often made from materials like polycarbonate, offer a more lightweight and cost-effective alternative. These visors are favored for their versatility, comfort, and clarity. Plastic visors are commonly used in a range of applications, from laboratories and healthcare settings to light industrial tasks. The material’s flexibility and affordability make plastic visors an attractive option for situations where impact resistance may be less severe.

Understanding the differences between metal and plastic visors is crucial in selecting the appropriate face protection based on specific needs and safety requirements. This exploration will delve into the distinct features of each type, helping individuals make informed decisions about the most suitable visor for their particular work environment or activity.

Plastic visors

Plastic visors are integral components of personal protective equipment, offering a versatile and cost-effective solution for various applications. Crafted from materials like polycarbonate, these visors provide a lightweight alternative to metal counterparts, making them comfortable for extended wear without compromising on durability. The inherent flexibility of plastic allows for greater design versatility, accommodating various face shapes and sizes.

One of the primary advantages of plastic visors is their impact resistance. Polycarbonate, a common material used in plastic visors, possesses remarkable strength, ensuring reliable protection against airborne particles, liquid splashes, and other potential hazards. The optical clarity of plastic visors remains excellent, providing wearers with a clear field of vision without distortion.

Plastic visors find widespread use in environments where the potential for heavy impact is lower, such as laboratories, healthcare settings, and light industrial work. Their affordability and disposable options make them accessible for single-use scenarios or situations where frequent replacements are necessary. Overall, plastic visors stand as a versatile and economical choice, catering to a range of safety needs across various industries.

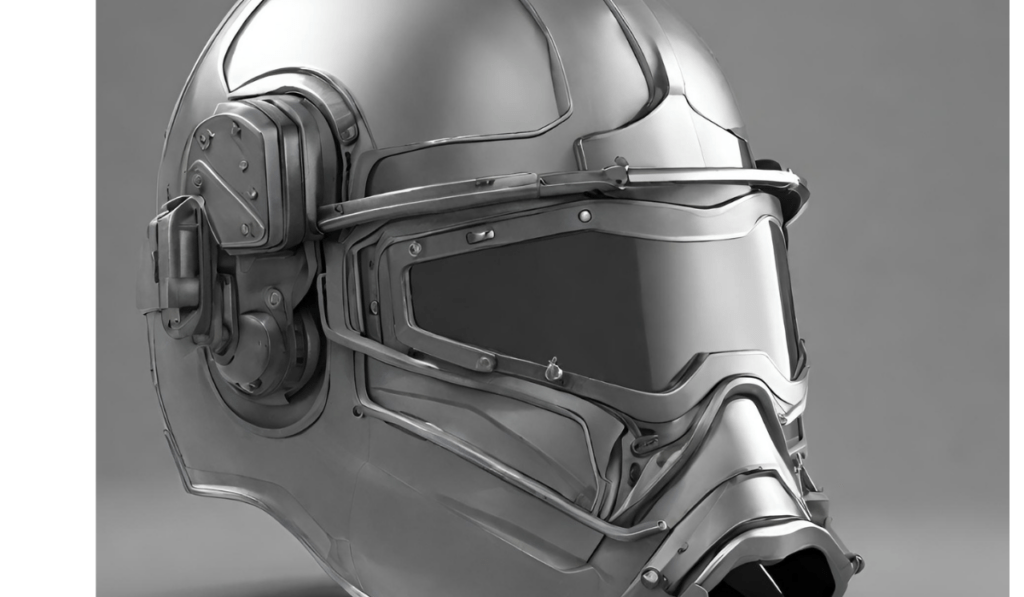

Metal visors

Metal visors are extremely durable and come in a wide variety of styles and prices. They are used to shield drivers from wind and debris and are available at different levels of opacity. Inexpensive metal visors will not protect against the sun, as well as more expensive items.

However, an inexpensive metal visor will look good on your car, and it won’t cost you an arm and a leg. With quality metal visors, you are looking at somewhere near $60 to $100. Metal visors are more durable than plastic, but that doesn’t mean they are heavy. Metal visors deflect light and heat aggressively. They offer an excellent level of protection but don’t provide full coverage.

Differences Between Metal and Plastic Visors

The differences between metal and plastic visors lie in their material composition, durability, and specific applications. Metal visors, commonly constructed from materials like aluminum or stainless steel, boast exceptional strength and durability, making them suitable for heavy-duty tasks where impact resistance is crucial. Industries such as construction and manufacturing often prefer metal visors due to their robust protective qualities.

On the other hand, plastic visors, typically made from materials like polycarbonate, offer a lightweight alternative with sufficient impact resistance. While not as sturdy as metal, plastic visors excel in environments where flexibility and comfort are paramount. They are commonly utilized in settings such as healthcare, laboratories, and light industrial work. Plastic visors are cost-effective and come in disposable options, making them suitable for scenarios where regular replacement is necessary.

The choice between metal and plastic visors depends on the specific safety requirements of the task at hand. Metal visors provide heavy-duty protection, while plastic visors offer versatility, comfort, and cost-effectiveness in environments with lower impact risks.

Pros of Metal visors

Metal visors offer a range of advantages, making them a preferred choice in certain industrial and heavy-duty settings. The primary pros of metal visors include their unparalleled durability and robustness. Constructed from materials like aluminum or stainless steel, these visors provide exceptional impact resistance, effectively shielding the wearer from heavy debris, sparks, or other hazards commonly found in construction and manufacturing environments.

Metal visors also boast a longer lifespan compared to their plastic counterparts, reducing the need for frequent replacements. Additionally, they maintain their structural integrity even in harsh conditions, making them a reliable choice for tasks that demand resilient face protection. The sturdiness of metal visors ensures that they provide a high level of safety, making them indispensable in occupations where maximum protection is paramount.

Pros of Plastic visors

Plastic visors offer several advantages, making them a popular choice for various applications. One significant pro is their lightweight design, providing comfort during extended wear without compromising on protection. Plastic visors, often made from materials like polycarbonate, deliver excellent impact resistance, effectively shielding wearers from airborne particles and liquid splashes. Their optical clarity ensures a clear field of vision without distortion, contributing to enhanced safety.

Plastic visors are also known for their affordability, making them a cost-effective option for industries with budget considerations. Their disposable options cater to scenarios requiring frequent replacements, such as in healthcare settings. Overall, the versatility, comfort, impact resistance, and cost-effectiveness make plastic visors a practical choice for environments with moderate safety requirements.

Cons of Metal visors

While metal visors offer robust protection, they come with certain drawbacks. One notable con is their weight and potential discomfort during prolonged use. The materials used, such as aluminum or stainless steel, contribute to a heavier visor, which can cause fatigue or strain on the wearer. The substantial weight may hinder mobility and comfort, particularly in tasks requiring extended periods of head movement.

Additionally, metal visors tend to be more expensive than their plastic counterparts, impacting their cost-effectiveness. Their conductivity can pose a safety concern in electrical work, as metal visors may conduct electricity. Lastly, metal visors can be prone to corrosion over time, especially in corrosive environments, potentially affecting their durability and lifespan. These factors highlight the importance of carefully considering the specific demands of the task and environment when choosing between metal and plastic visors.

Cons of Plastic visors

Despite their advantages, plastic visors come with certain drawbacks that may influence their suitability for specific applications. One notable con is their reduced durability compared to metal visors. While plastic, particularly polycarbonate, offers good impact resistance, it may not withstand heavy-duty tasks or extreme conditions as effectively as metal. Plastic visors are also more prone to scratching, potentially impairing visibility over time. In high-heat environments, some plastic visors may be susceptible to distortion or warping.

Additionally, their disposability, while cost-effective, contributes to environmental concerns with increased waste. When exposed to certain chemicals, plastic visors may degrade or lose their clarity. Evaluating these limitations is crucial in determining whether plastic visors align with the safety requirements and conditions of the intended application.

When to use a metal visor

These days, you don’t have to choose between metal and plastic, as various hybrid visors on the market incorporate both materials. These types of visors can often be found with a tint or tint and tint protection film.

All-metal is the most durable type of visor, made from metal. As metal can withstand higher temperatures than plastic, it can make for an excellent visor for all weather.

When to use a plastic visor

When the temperature is high, a plastic visor offers an excellent and affordable way to provide an extra level of protection. In particular, this is the case for areas such as the inside of the windshield, where no amount of tint will filter the sun’s rays.

The outer plastic layer on the bottom of the visor protects the glass and is also waterproof. The strength of the plastic material is the major reason why plastic is used in a lot of visors.

How to clean the visors

It’s simple – a metal visor is easy to clean because it is made of stainless steel. Wipe the visor down with a damp cloth to remove dust and debris. Clean a window-tinted visor with a strong quality window cleaner to eliminate any dust and clean the metal surface. To remove odors, use a paper towel to remove any excess moisture and rinse out the visor.

Cleaning visors is essential for maintaining visibility and ensuring their effectiveness in protecting against hazards. Here’s a step-by-step guide on how to clean visors:

Remove the Visor: Detach the visor from the helmet or headgear, following the manufacturer’s instructions.

Inspect for Damage: Check the visor for any scratches, cracks, or other damage. If damaged, consider replacing it for optimal protection.

Dust Removal: Gently remove loose dirt and dust using a soft brush or compressed air. This prevents scratching during the cleaning process.

Wash with Mild Soap: Prepare a mixture of mild soap and warm water. Using a soft cloth or sponge, gently wipe both sides of the visor to remove grime and residue.

Rinse Thoroughly: Rinse the visor with clean water to remove soap residue. Ensure thorough rinsing to prevent any leftover soap from affecting visibility.

Air Dry or Pat Dry: Allow the visor to air dry or pat it dry with a clean, lint-free cloth. Avoid using abrasive materials that could scratch the surface.

Reattach to Helmet: Once completely dry, reattach the visor to the helmet or headgear according to the manufacturer’s instructions.

Regularly cleaning visors helps maintain clarity and ensures they provide optimal protection in various work environments.

What are the benefits of the metal visor?

Metal visors offer several benefits, making them a preferred choice in specific industrial settings. One notable advantage is their unparalleled durability and strength. Constructed from materials like aluminum or stainless steel, metal visors provide robust protection against heavy impact, debris, and sparks, ensuring enhanced safety in tasks common to construction and manufacturing environments. Their longevity surpasses that of plastic visors, reducing the need for frequent replacements.

Additionally, metal visors maintain structural integrity even in harsh conditions, making them reliable for tasks demanding resilient face protection. Their sturdiness ensures maximum safety, providing wearers with a high level of confidence in hazardous work scenarios. The durability and impact resistance of metal visors makes them indispensable for occupations requiring uncompromising protection and longevity in the face of demanding conditions.

What are the benefits of plastic visors?

Plastic visors offer several advantages over their metal counterparts. First, they’re lighter. Not only that, but they don’t scratch and be easier to clean, as you don’t have to deal with hinge or hinge materials. Most plastic visors also use plastic hinges to make them lighter. They’re designed with lightness in mind.

This is big, as a lighter visor will decrease the strain on your eyes when you drive. Plastic visors also offer some benefits for your visibility. Plastic visors are lighter and less reflective than reflective metal, which allows you to see more clearly in the sun. These visors also use mesh so that you can see better when driving in the rain.

Which one is better?

The choice between a metal or plastic visor depends on specific application requirements and individual preferences. Metal visors excel in heavy-duty environments where robust protection against significant impact, sparks, or debris is essential, such as in construction or manufacturing. Their durability and strength make them a superior choice for tasks demanding uncompromising face protection and longevity.

On the other hand, plastic visors offer versatility, comfort, and cost-effectiveness, making them suitable for environments with moderate safety requirements. They are lightweight, providing comfort during extended wear, and their impact resistance is adequate for various applications, particularly those with lower risk levels.

Ultimately, the decision should be based on the nature of the work, the level of protection required, and considerations like comfort, weight, and cost. For heavy-duty tasks, a metal visor may be preferable, while a plastic visor may be more practical for lighter applications. It’s essential to assess specific needs and choose the visor type that best aligns with the demands of the task and the working environment.

Frequently Asked Questions (FAQs)

Are metal visors more expensive than plastic visors?

Yes, metal visors are often more expensive than plastic visors. The cost of materials and the manufacturing process contribute to the higher price of metal visors, while plastic visors offer a more budget-friendly option.

Can plastic visors be used in healthcare settings?

Yes, plastic visors are commonly used in healthcare settings. Their lightweight design, comfort, and impact resistance make them suitable for protecting against splashes and minor impacts in medical environments.

Are metal visors more durable than plastic visors?

Yes, metal visors are generally more durable than plastic visors. The strength and resilience of materials like aluminum or stainless steel contribute to the longevity of metal visors, making them suitable for heavy-duty tasks.

Where can I find the E3 Spark Plugs Cross Reference Chart?

The E3 Spark Plugs Cross Reference Chart is available on the official E3 website and through authorized retailers. It’s a valuable resource for matching your E3 spark plug model with compatible alternatives.

Can I use any spark plug as a replacement for my E3 spark plug?

It’s recommended to consult the E3 Spark Plugs Cross Reference Chart to find a compatible replacement. While some spark plugs may fit physically, variations in heat range and specifications can affect engine performance.

Conclusion

The choice between a metal and plastic visor largely depends on individual preferences, specific use cases, and safety considerations. Metal visors, often made of materials like aluminum or stainless steel, offer durability and robustness, making them suitable for heavy-duty applications where impact resistance is crucial. On the other hand, plastic visors, crafted from materials such as polycarbonate, provide a lightweight and more budget-friendly alternative, ideal for tasks where flexibility and comfort are paramount. While metal visors may excel in certain industrial settings, plastic visors are often favored for their versatility and affordability. Ultimately, selecting the right visor involves assessing the nature of the task at hand, comfort requirements, and adherence to safety standards to ensure optimal eye and face protection in various working environments.